Introduction

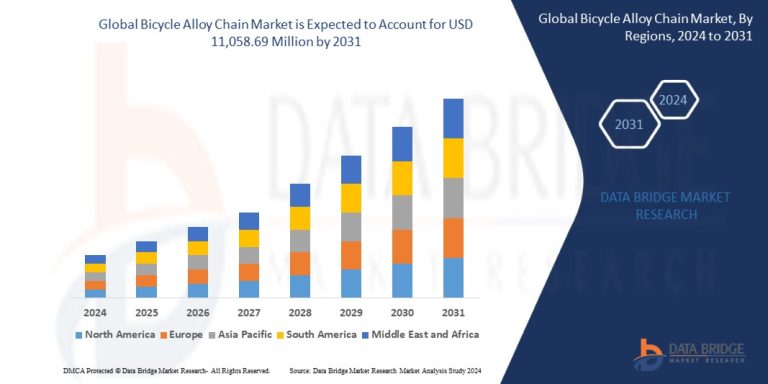

The Bicycle Alloy Chain Market is a pivotal segment in the global cycling industry, driven by the rising demand for lightweight, durable, and high-performance drivetrain components. Alloy chains, typically made from steel, aluminum, or titanium blends, are engineered to optimize power transfer, reduce friction, and withstand diverse riding conditions. As cycling gains traction as a sustainable mode of transport, a fitness activity, and a competitive sport, the market for alloy chains is expanding rapidly. The surge in electric bikes (e-bikes), urban mobility initiatives, and performance cycling is reshaping the landscape of chain technology and consumer expectations.

The Evolution

Bicycle chains have evolved significantly since their inception in the late 19th century. Early chains were heavy, single-speed, and prone to corrosion. The introduction of alloy materials revolutionized chain design, enabling lighter, stronger, and more corrosion-resistant products. The shift from basic steel to high-tensile alloys allowed for the development of multi-speed drivetrains, enhancing gear efficiency and rider control.

The evolution accelerated with the rise of e-bikes and high-performance road and mountain bikes. These applications demanded chains capable of handling increased torque, rapid shifting, and extreme environmental conditions. Manufacturers responded with innovations such as hollow pins, nickel plating, and advanced surface treatments. Today’s alloy chains are precision-engineered for specific use cases, from urban commuting to competitive racing.

Source : https://www.databridgemarketresearch.com/reports/global-bicycle-alloy-chain-market

Market Trends

- E-Bike Integration E-bikes require chains that can endure higher torque and frequent acceleration. Alloy chains with reinforced links and anti-corrosion coatings are becoming standard in this segment.

- Lightweight Performance Focus Competitive cyclists prioritize weight reduction. Titanium and aluminum alloy chains are favored for their strength-to-weight ratio and minimal drag.

- Customization and Aesthetic Appeal Riders seek chains in various colors and finishes. Anodized and laser-etched chains are gaining popularity among enthusiasts.

- Sustainability and Recyclability Manufacturers are adopting recycled metals and eco-friendly production methods to align with environmental goals.

- Smart Chain Technology Integration of sensors and wear indicators is emerging, enabling predictive maintenance and performance monitoring.

- Gravel and Adventure Cycling Growth Demand for versatile, high-durability chains is rising with the popularity of gravel and mixed-terrain cycling.

Challenges

- High Manufacturing Costs Alloy chains are more expensive to produce than traditional steel chains, limiting accessibility in budget segments.

- Material Price Volatility Fluctuations in the cost of titanium, aluminum, and steel alloys impact production planning and pricing strategies.

- Compatibility Constraints Not all alloy chains are compatible with every drivetrain system, leading to consumer confusion and returns.

- Durability vs. Weight Trade-offs Lighter chains may compromise on longevity, especially under high-stress conditions like mountain biking or e-bike use.

- Counterfeit and Low-Quality Imports The market faces challenges from imitation products that undermine brand trust and performance standards.

- Limited Recycling Infrastructure While alloy chains are recyclable, many regions lack the facilities to process them efficiently.

Market Scope

- Application Segments

- Road Bikes

- Mountain Bikes

- Hybrid and Commuter Bikes

- Electric Bikes

- BMX and Freestyle Bikes

- Gravel and Touring Bikes

- Material Types

- Aluminum Alloy

- Titanium Alloy

- Steel Alloy

- Carbon Composite

- Distribution Channels

- Online Retail

- Specialty Bicycle Stores

- OEM Supply Chains

- Wholesale Distributors

- End Users

- Professional Cyclists

- Recreational Riders

- Urban Commuters

- Bike-Sharing Fleets

- Geographic Segmentation

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa.

Factors Driving Growth

- Urban Mobility Initiatives Cities are investing in cycling infrastructure, boosting demand for reliable and efficient bicycle components.

- Health and Fitness Trends Cycling is increasingly embraced as a low-impact exercise, fueling demand for performance-grade chains.

- Government Incentives Subsidies for e-bikes and green transportation are accelerating market expansion.

- Technological Advancements Innovations in metallurgy and chain design are enhancing product performance and lifespan.

- Aftermarket Demand Cyclists frequently upgrade or replace chains, creating a robust aftermarket ecosystem.

- Brand Collaborations Partnerships between chain manufacturers and bicycle brands are driving co-branded, high-performance offerings.

Conclusion

The Bicycle Alloy Chain Market is poised for sustained growth, driven by innovation, environmental awareness, and the global shift toward active transportation. While challenges such as cost and compatibility persist, the market’s trajectory is upward, supported by technological breakthroughs and evolving consumer preferences. Manufacturers that prioritize quality, sustainability, and customization will lead the charge in shaping the future of cycling performance.